When choosing ferrosilicon powder, many buyers focus mainly on silicon content. But, in real production, particle shape, production method, and cost-performance balance are often more important than chemistry alone.

The choice between milled ferrosilicon powder and atomized ferrosilicon powder should be made based on industry application, process tolerance, and cost sensitivity.

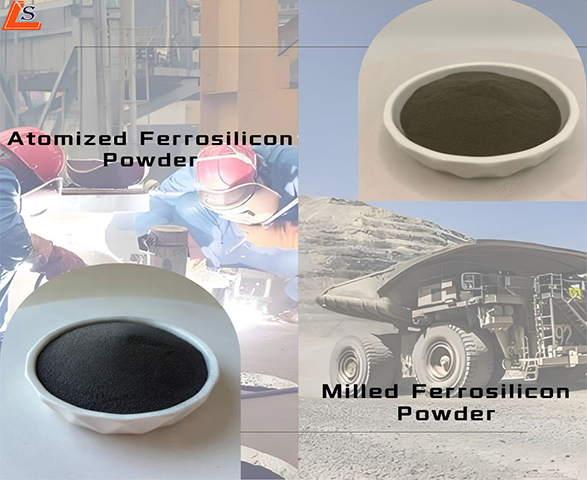

1. Understanding Milled and Atomized Ferrosilicon Powder

Atomized ferrosilicon powder is produced by spraying molten ferrosilicon through water or gas.

This process creates spherical particles with smooth surfaces and low oxidation.

Milled ferrosilicon powder is made by crushing and grinding ferrosilicon lumps.

The particles are irregular and angular, with a wider size distribution.

Although their chemical compositions are similar, their physical behavior in use is very different.

2. Industry-Based Selection Guide

Welding Electrodes and Welding Wires

For welding electrodes and flux-cored wires, stable flow and consistent reaction are critical.

* Atomized ferrosilicon powder offers:

* Better flowability.

* Lower dust.

* More stable silicon recovery.

**Recommended choice: Atomized ferrosilicon powder.

**Reason: Quality consistency is more important than material cost.

Dense Media Separation (DMS) and Mineral Processing

In DMS systems, the key factors are medium density, viscosity, and suspension stability.

* Atomized ferrosilicon powder:

* Lower viscosity.

* Easier to reach high density.

* Milled ferrosilicon powder:

* Better suspension

* Slower settling

**Recommended choice:

* High-density or precision separation → Atomized powder.

* Standard separation with cost control → Milled powder.

Steelmaking and Metallurgy

In steelmaking, ferrosilicon powder is often used as a deoxidizer or silicon additive.

* Atomized ferrosilicon powder provides:

* Faster and more predictable reaction.

* Higher effective silicon recovery.

* Milled ferrosilicon powder offers:

* Lower purchase cost.

* Acceptable performance in non-critical stages.

**Recommended choice:

* Precise composition control → Atomized ferrosilicon powder.

* Large-volume, cost-sensitive deoxidation → Milled ferrosilicon powder.

Mineral Beneficiation and General Industrial Use

For applications where process tolerance is high and cost is the main concern, milled ferrosilicon powder is widely used.

**Recommended choice: Milled ferrosilicon powder.

**Reason: Best balance between performance and price.

3. Cost Considerations: Comparing Milled vs Atomized Ferrosilicon Powder Beyond Unit Price

A common mistake is comparing only the price per ton.

The real comparison should be based on:

* Flowability and handling loss.

* Oxidation and dust generation.

* Effective silicon recovery in the process.

In many cases:

* Atomized ferrosilicon powder has a higher unit price but lower total cost per effective silicon.

* Milled ferrosilicon powder has a lower unit price but may require higher consumption.

The right choice depends on total cost, not purchase price.

4. Practical Purchasing Strategy for Milled and Atomized Ferrosilicon Powder

Many experienced users do not choose only one type.

A common strategy is:

* Atomized ferrosilicon powder for key or sensitive processes.

* Milled ferrosilicon powder for high-volume, cost-driven applications.

This approach allows companies to control quality while managing costs effectively.

5. Conclusion

There is no “best” ferrosilicon powder for all applications. The correct decision should always be based on industry requirements, process conditions, and total cost performance.

At LSFerroalloy, we provide both milled and atomized ferrosilicon powder, ensuring the highest quality for a wide range of applications. With consistent particle size and precise quality control, we help clients optimize their processes and reduce costs. Whether you need precise control or cost-effective solutions, our products are engineered to meet your needs.